|

PRESSURE TESTING PROCEDURE

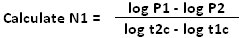

Take a first reading of pressure P1 at t1, where t1 is equal to the pressure loading time tL.

Note t1c = t1 corrected = t1 + 0.4tL

Take a second reading of pressure P2, at a decay time of approximately 7tL this is time t2.

Note t2c = t2 corrected = t2 + 0.4tL

For a sound main this ratio N1 should be:

a) 0.08 to 0.10 for pipes without constraint (e.g. sliplined or not backfilled)

b) 0.04 to 0.05 for pipes with compacted backfill.

If the values are significantly less than the minimum identified, then there is too great a volume of air in the pipework. This air will have to be removed before a satisfactory test can be performed. Experience shows that re-testing can be significantly more difficult to carry out because the pipe has already stretched due to creep from the pressure originally applied.

It is therefore of extreme importance to ensure that air is removed prior to testing.

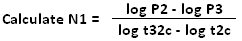

Take a further reading of pressure P3 at a decay time not less than 15tL. Let this time be t3.

Note t3c = t3 corrected = t3 + 0.4tL

The ratio for N2 should be

a) 0.08 to 0.10 for pipes without soil constraint

b) 0.04 to 0.05 for pipes with compacted backfill.

The sensitivity of the test can be increased by extending the value of t3.

If at any stage during this pressure test an unacceptable leak is indicated, it is advisable to check all mechanical fittings before visually inspecting the welded joints. Any defect in the installation revealed by the test should, of course, be rectified and the test repeated.

On completion of a test sequence the remaining pressure should be released slowly until the pipeline is under its pre-test conditions.

In the event of a further test being required on the pipeline, such a test should NOT be attempted before sufficient time has elapsed for the pipeline to recover from the previously imposed conditions. This recovery time will depend upon individual circumstance but a period equivalent to 5 times the previous test period may be taken as a guide.

Back to previous page

|